Zircotec unveil world-first ceramic coatings that enable new lightweight Electric Vehicle (EV) battery and cooling plate designs

Proprietary coatings unlock new lightweight material possibilities for OEMs, supporting efforts to reduce vehicle weight, enhance range and boost safety

New proprietary coatings allow lightweight aluminium, plastic and composite materials to be used instead of steel

Coatings combine dielectric and flameproofing properties to solve thermal management and electrical insulation challenges in EVs

Improved cooling plate efficiency through thin, high-performance insulation with enhanced thermal conductivity

Proven through rigorous thermal runaway testing (UL2596), confirming high performance under extreme conditions

Pioneering research programme has lasted 12 months and been delivered with the help of government funding through the Advanced Propulsion Centre UK (APC)

Zircotec and Cranfield University have collaborated on the project, with the latter delivering coating expertise through testing, evaluation, and implementation of novel future technologies

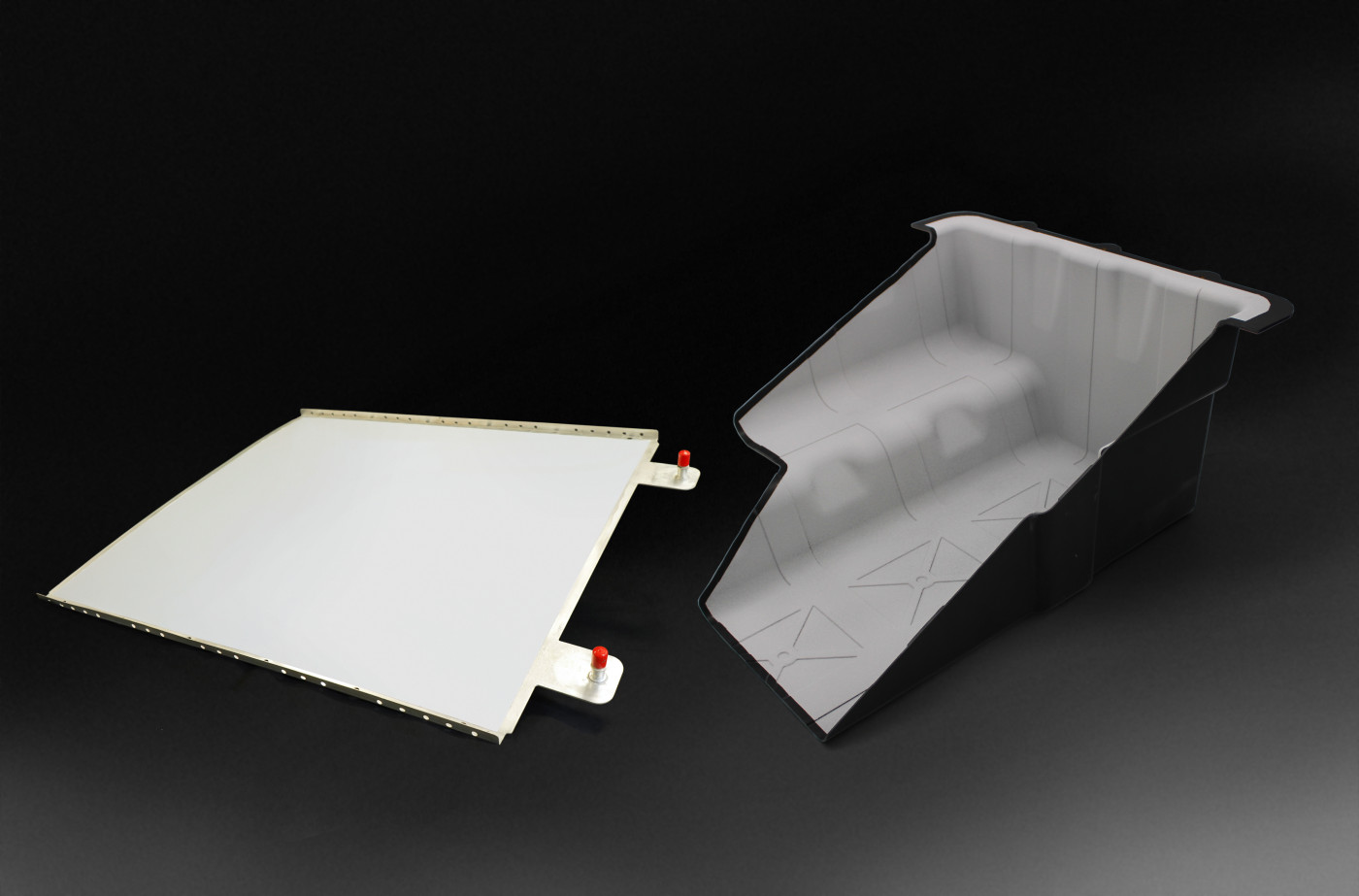

03 September 2025 – Abingdon: Zircotec has unveiled a new range of proprietary ceramic coatings on the first day of the UK’s Cenex Expo 2025 (stand C2-233) that make it possible for EV manufacturers to replace heavy-duty steel battery enclosures and cooling plates with lightweight aluminium and plastic composite materials – without compromising safety, thermal management or electrical insulation.

The coatings are the result of the partly government-funded CeraBEV (Ceramics for BEVs) project, comprising a consortium led by Zircotec and with Cranfield University as a key project partner. Delivered with the support of the Advanced Propulsion Centre UK (APC), CeraBEV’s remit was to accelerate the UK’s capability in safe battery energy storage technology.

Developed by the Zircotec engineering team in Abingdon, Oxfordshire, the ‘ElectroHold’ coatings integrate dielectric, flameproofing and thermal properties into a single coating system. This allows OEMs to use lighter materials for battery enclosures and to improve cooling plate efficiency by pairing thin, high-performance electrical insulation with enhanced thermal conductivity. The result is greater design flexibility, reduced vehicle weight and extended driving range.

“We’ve used our thermal management expertise to develop multifunctional coatings that address the new challenges of electrification,” Dominic Graham, Zircotec Engineering Director, explained. “They provide outstanding protection against heat and flame, ensure greater electrical insulation needed for safety, and improve thermal transfer. That’s a combination that has the potential to transform the EV industry by unlocking the use of lightweight materials across battery boxes and cooling plates.”

Zircotec’s new coatings have been subjected to rigorous electrical, thermal and durability testing, simulating the demands of modern EV motoring. This included a full-scale simulated ‘UL2596 Method A’ thermal runaway test event for the battery box coating where the battery module was deliberately driven to failure to replicate the most severe safety scenario an EV might encounter.

During this test, the Zircotec-coated carbon fibre enclosure passed comfortably, maintaining its structural integrity, preventing flame egress and continuing to provide electrical isolation – demonstrating its ability to increase all-important protection time for vehicle occupants and surrounding systems under extreme heat and pressure.

During other tests, simulations and evaluations, conducted in partnership with Cranfield University and HORIBA MIRA, Zircotec’s latest cooling plate coating delivered a four-fold increase in dielectric strength over a previous iteration. The coatings also proved resistant to mechanical stress, corrosion, chemical attack and a wide range of temperatures, confirming their suitability for both high-performance and mass-market automotive applications. Thermal conductivity measurements were carried out using equipment accessed via the Royal Institute in Sheffield, while BeonD contributed to battery propagation safety testing.

Terry Graham, Zircotec CEO, said: “As thermal technologists that have defined the science of heat management for more than 30 years, we’re delighted with the results of the CeraBEV project. Thanks to our strong collaboration with Cranfield University and other industry partners, we firmly believe these proprietary coatings have the potential to revolutionise the global EV market by unlocking the use of prized lightweight materials.

“This technology is now ready for OEMs to integrate into their production programmes and we’re proud that it’s been UK material science, coating and engineering expertise and collaborations that have led us to this transformative position.”

Dave Matthews, Senior Project Delivery Lead, APC said: “Drawing upon a rich legacy of innovation in thermal management, Zircotec is now focusing its expertise on the advancement of new energy vehicles. Reducing mass is vital, and leveraging alternative materials plays a pivotal role in achieving lightweighting. Advanced coatings not only support the use of these innovative materials but also uphold safety and structural integrity.

“The Demonstrate funding stream is designed to propel companies in their product development journeys, facilitating the swift transition of groundbreaking technologies into the marketplace. By fostering collaboration between industry and academia, APC aims to bring the most pioneering and impactful solutions to fruition.”